Sustainable Packaging Materials

Path To Sustainability: Reduce

If you’re looking to improve your packaging sustainability without compromising performance, one of the most effective solutions is to switch to thinner materials.

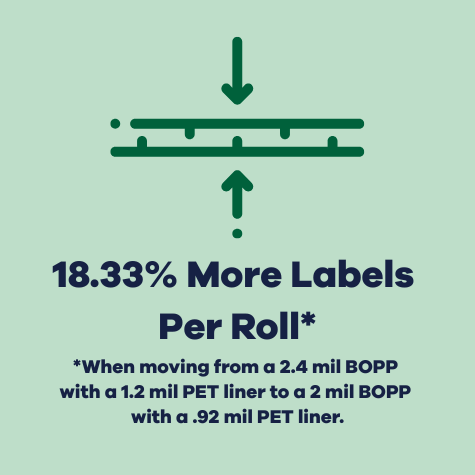

Using sustainable packaging materials by choosing thinner materials — such as moving from a 2.3 mil white BOPP face stock to a 2.0 mil, or from a 1.2 mil PET liner to a .92 mil PET — can result in meaningful savings and reductions in environmental impact.

Why Thinner Materials Matter

By switching to thinner label and liner materials, you can:

- Reduce material waste

- Lower overall material costs

- Fit more labels per roll, increasing efficiency

- Decrease freight and shipping costs due to lighter, more compact rolls

For example, replacing 60# paper face stocks with 48# alternatives not only conserves raw materials, but also allows more labels to be wound onto a single roll — maximizing throughput and minimizing downtime.

By using thinner materials, you can reduce the amount of changeovers you have in the plant. One of our customers saw a 67% increase in productivity from changing to thinner stocks. The best part, the label was also approved for recycling, making their entire package 100% recyclable.

Engineered for Performance

Our thinner materials are not only more sustainable — they’re designed to perform. Many of our options offer better tension resistance and improved productivity compared to their thicker counterparts, making them ideal for high-speed applications.

We Help You Test for Success

Not sure if thinner materials will work for your application? We’re here to help. Our team provides testing and validation support to ensure your packaging performs as expected — before you commit.

Ready to explore thinner, more sustainable packaging materials?

Let’s talk about how we can help you cut costs, reduce waste, and support your sustainability goals — all by choosing smarter, thinner materials.

Explore the Other Sustainability Paths

RECYCLABLE

REPURPOSED

RENEWABLE

BIODEGRADABLE